Mastering Vehicle Safety: An In-Depth Guide to Slack Adjusters in Braking Systems

Understanding Slack Adjusters

In the realm of vehicle braking systems, the significance of slack adjusters cannot be overstated. As the foundational element ensuring efficient braking performance, understanding slack adjusters is paramount for vehicle owners and operators alike.

What Are Slack Adjusters?

Slack adjusters are pivotal mechanical components that bridge the gap between brake shoes and drum brakes within vehicles. Their primary role is to maintain the optimal clearance between these components as they wear down over time, thereby guaranteeing consistent and reliable braking performance. This systematic adjustment prevents issues like excessive brake shoe travel, which can lead to reduced braking efficiency and even brake lock-ups.

Importance of Proper Adjustment

Properly adjusted slack adjusters are integral to road safety. When these components are functioning optimally, vehicles can achieve maximum braking potential, minimizing the risk of accidents caused by inadequate stopping distances. Moreover, balanced brake adjustment extends the lifespan of braking system components, reducing maintenance costs and downtime for vehicle operators.

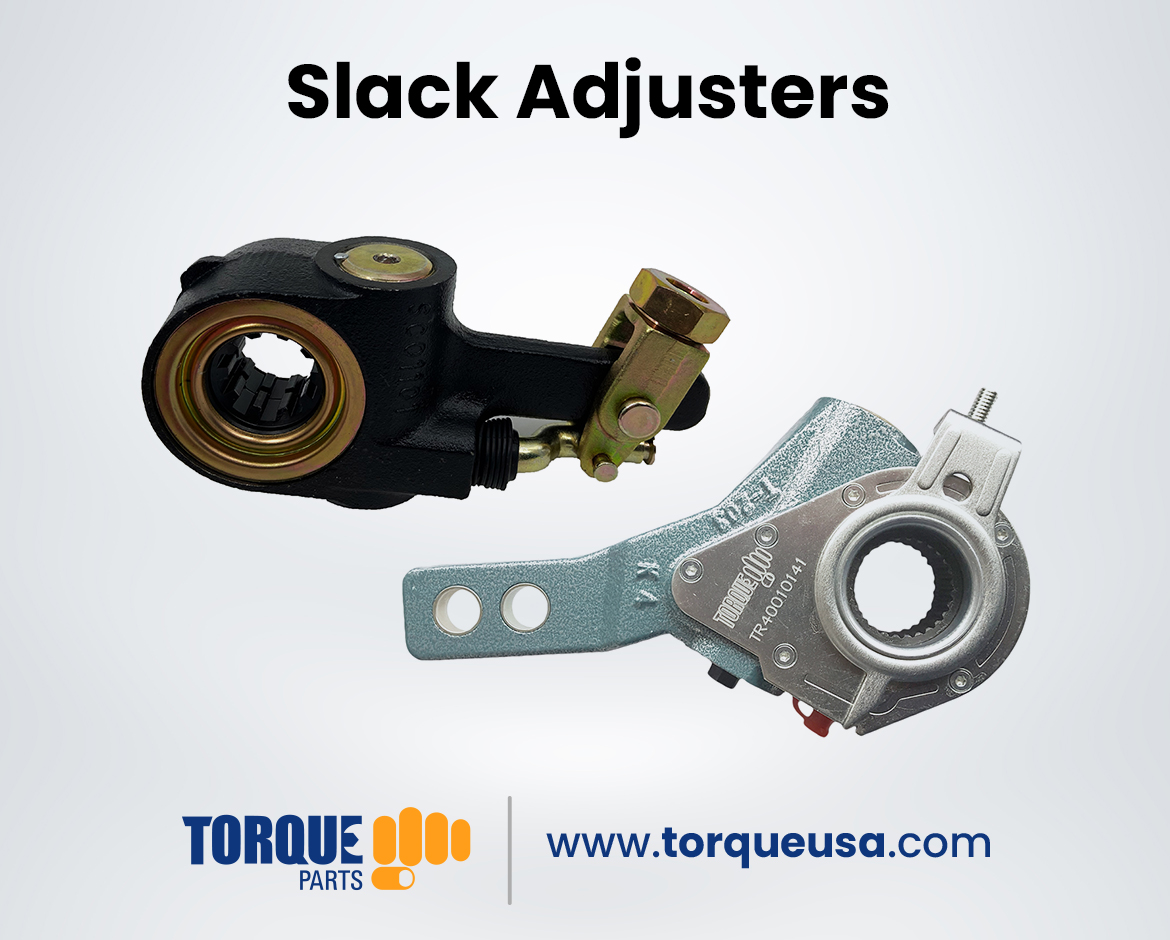

Types of Slack Adjusters

Two main types of slack adjusters dominate the market: manual and automatic. Manual slack adjusters require regular manual adjustments, making them suitable for specific applications. On the other hand, automatic slack adjusters utilize mechanical or air-powered mechanisms to automatically compensate for brake shoe wear, reducing the need for frequent manual interventions.

Conclusion

Understanding the role of slack adjusters is fundamental to comprehending how braking systems work and ensuring road safety. As we proceed through this guide, we’ll delve deeper into the intricacies of different slack adjuster types, their mechanisms, maintenance, and their overall contribution to maintaining efficient braking systems.

Types of Slack Adjusters

In the world of vehicle braking systems, the concept of slack adjustors manifests in various forms, each designed to cater to specific operational needs. This chapter sheds light on the diverse landscape of slack adjustors, exploring both manual and automatic variants and their distinct advantages.

Manual Slack Adjusters: A Hands-On Approach

Manual slack adjusters, as the name implies, demand regular manual adjustments to maintain the appropriate brake shoe-to-drum clearance. These adjusters offer simplicity and cost-effectiveness, often found in applications where constant monitoring and adjustment are feasible. Their straightforward design makes them well-suited for certain vehicles and scenarios.

Automatic Slack Adjusters: Streamlining Maintenance

In contrast, automatic slack adjusters revolutionize the maintenance landscape by autonomously compensating for brake shoe wear. Utilizing mechanical or air-powered mechanisms, these adjusters guarantee that the optimal clearance is consistently maintained without manual intervention. This feature not only enhances braking efficiency but also reduces the workload of vehicle operators and minimizes the risk of human error.

Choosing the Right Type

Selecting the appropriate slack adjuster type depends on various factors, including vehicle usage, operational environment, and maintenance resources. Vehicle operators must evaluate these factors to make informed decisions that align with safety requirements and operational efficiency.

Benefits of Each Type

Manual adjusters’ simplicity often translates to ease of maintenance and cost savings, while automatic adjusters excel in reducing downtime, ensuring consistent braking performance, and decreasing the likelihood of brake-related accidents.

Conclusion

The choice between manual and automatic slack adjusters isn’t just a technical decision; it’s a strategic one that influences the safety, efficiency, and overall operational costs of a vehicle. By understanding the distinctions between these types, operators can make educated choices that contribute to safer and more reliable braking systems.

How Slack Adjusters Work

In the intricate symphony of vehicle braking systems, slack adjusters play a pivotal role in harmonizing the components for optimal performance. This chapter delves into the mechanics behind slack adjusters, elucidating their function in maintaining the delicate balance between brake shoes and drums.

Balancing the Distance: A Crucial Task

At its core, the role of a slack adjuster is to manage the gap between the brake shoe and the drum as the brake system operates. As brake shoes wear down over time, this gap increases, potentially leading to reduced braking efficiency and safety risks. The slack adjuster counteracts this wear, ensuring that the appropriate distance is maintained for effective braking.

The Linkage System: Connecting the Dots

The mechanism by which slack adjusters achieve their mission is typically a linkage system. When the brake is applied, the actuator transfers force to the slack adjuster, which then rotates. This rotation results in the adjustment of the pushrod, effectively compensating for the wear in the brake shoes. The linkage system ensures that the adjustment is proportional to the wear, optimizing the braking process.

Manual vs. Automatic Mechanisms

Both manual and automatic slack adjusters employ this basic principle, but their mechanisms differ. Manual adjusters require regular manual adjustments to maintain the correct clearance, while automatic adjusters feature self-adjusting mechanisms driven by mechanical or pneumatic forces. This automatic adjustment system enhances braking efficiency and reduces the need for frequent manual intervention.

Safety and Efficiency

Understanding the inner workings of slack adjusters illuminates their significance in ensuring safe and efficient braking systems. Properly functioning slack adjusters contribute to shorter stopping distances, reduced wear on braking components, and overall safer road conditions.

Conclusion

Mastering how slack adjusters work is key to comprehending the complexity of braking systems. With this knowledge, vehicle operators and maintenance personnel can appreciate the precision required to maintain these vital components and contribute to road safety.

Signs of Worn-Out Slack Adjusters

In the realm of vehicle maintenance, recognizing signs of wear is akin to interpreting the language of the machine. This chapter delves into the telltale signs that indicate worn-out slack adjusters, providing crucial insights to prevent potential brake system failures and maintain road safety.

Reduced Braking Performance: A Red Flag

One of the earliest indicators of worn-out slack adjusters is a noticeable reduction in braking performance. If you find that your vehicle takes longer to come to a stop or requires more force on the brake pedal, it could be a sign that the brake shoes aren’t engaging properly due to improper slack adjuster functioning.

Unusual Noises: Squeaks and Squeals

Worn-out slack adjusters can cause unusual noises while braking. Squeaking, squealing, or grinding sounds can signify that the brake shoes are not making proper contact with the drum. These noises are warning signals that warrant immediate attention.

Uneven Brake Pad Wear: An Imbalanced Situation

Inspecting the brake pads for uneven wear patterns can provide insights into the condition of the slack adjusters. If one side of the brake pad is wearing significantly faster than the other, it may indicate an imbalance due to slack adjuster malfunction.

Excessive Brake Pedal Travel: An Obvious Clue

Excessive brake pedal travel, where the pedal goes down much further than usual before engaging the brakes, could suggest slack adjuster issues. This increased pedal travel can stem from the brake shoes not being properly adjusted, reducing braking efficiency.

Conclusion

Vigilance in identifying signs of worn-out slack adjusters is a proactive measure that enhances road safety. By staying attuned to reduced braking performance, unusual noises, uneven brake pad wear, and excessive pedal travel, vehicle owners and operators can address slack adjuster problems promptly, ensuring that the braking system remains reliable and effective.

Regular Maintenance and Inspection of Slack Adjusters

In the intricate choreography of vehicle maintenance, consistent care and attention are essential to ensure optimal performance. This chapter emphasizes the importance of regular maintenance and inspection routines for slack adjusters, illuminating the path to sustained braking efficiency and enhanced road safety.

Scheduled Inspections: Preventive Vigilance

Implementing a scheduled inspection regimen is fundamental in maintaining slack adjusters. Regular checks allow operators to identify early signs of wear or malfunction, enabling timely interventions that prevent minor issues from escalating into major problems.

Cleaning and Lubrication: Nurturing Functionality

Cleaning and lubricating slack adjusters are simple yet effective maintenance practices. Removing dirt, debris, and rust helps preserve their functional integrity. Applying appropriate lubricants ensures smooth movement of components, preventing excessive wear due to friction.

Manual Slack Adjusters: Hands-On Precision

For vehicles equipped with manual slack adjusters, consistent manual adjustments are critical. Regularly measure the clearance between brake shoes and drums and make necessary adjustments to ensure the optimal distance is maintained.

Automatic Slack Adjusters: Monitoring and Validation

Vehicles outfitted with automatic slack adjusters require diligent monitoring. Regularly inspect the adjusters to ensure they are functioning correctly. Engage in system validations to confirm that the automatic adjustment mechanisms are working as intended.

Documentation and Records: A Systematic Approach

Maintain a comprehensive record of maintenance activities related to slack adjusters. Document inspections, adjustments, lubrication, and any replacements performed. This documentation not only aids in tracking the maintenance history but also supports compliance with regulatory requirements.

Conclusion

Regular maintenance and inspections of slack adjusters are integral to the longevity and reliability of vehicle braking systems. By adhering to a well-structured maintenance routine, operators uphold optimal braking performance, contributing to safer road conditions and bolstering overall vehicle efficiency.

Replacing Slack Adjusters

In the life cycle of vehicle components, there comes a time when replacement becomes inevitable. This chapter addresses the intricate process of replacing slack adjusters, guiding readers through the necessary steps to ensure a seamless transition and sustained braking system efficiency.

Diagnosis and Evaluation: Identifying the Need

Before initiating the replacement process, conduct a thorough diagnosis of the slack adjuster. Confirm that the issues aren’t related to adjustment, lubrication, or other fixable factors. Once you determine that replacement is necessary, proceed with the process.

Gathering the Right Tools: Preparedness is Key

Equipping yourself with the appropriate tools is crucial for a successful slack adjuster replacement. This may include wrenches, pliers, brake cleaning solution, and replacement parts. Having everything on hand saves time and ensures a smooth workflow.

Step-by-Step Replacement Procedure: A Methodical Approach

The replacement procedure generally involves loosening and removing the old slack adjuster, cleaning the area, and installing the new component. Follow manufacturer guidelines and specifications meticulously to ensure proper fit and function.

Adjustment and Calibration: Fine-Tuning for Optimal Performance

After the new slack adjuster is installed, it’s essential to perform the necessary adjustments and calibrations. This ensures that the brake shoes maintain the correct clearance with the drum, guaranteeing optimal braking performance.

Testing and Validation: Ensuring Success

Conduct a comprehensive test of the brake system after the replacement. Ensure that the brakes engage properly and that the vehicle comes to a stop smoothly. Test in controlled conditions before resuming regular operations.

Conclusion

Replacing slack adjusters demands precision and adherence to guidelines. By following a systematic approach, vehicle operators and maintenance personnel can confidently navigate the replacement process, restoring braking efficiency and contributing to overall road safety.

Importance of Properly Functioning Slack Adjusters

In the intricate machinery of a vehicle, even the smallest component can have a monumental impact on overall performance. This chapter delves into the far-reaching importance of properly functioning slack adjusters in maintaining efficient braking systems and ensuring a safe and smooth journey on the road.

Braking Efficiency: The Ultimate Goal

At the heart of the matter lies the core objective of slack adjusters – optimizing braking efficiency. These components play a pivotal role in maintaining the ideal distance between brake shoes and drums. Proper adjustment guarantees consistent and effective braking, reducing the risk of accidents and ensuring the safety of passengers and pedestrians alike.

Reduced Downtime: A Financial Advantage

Vehicles with well-maintained slack adjusters experience fewer instances of unexpected brake-related breakdowns. This translates to reduced downtime and operational disruptions, saving valuable time and resources for vehicle operators and businesses.

Regulatory Compliance: Navigating Safety Standards

Properly functioning slack adjusters are essential for complying with safety regulations. Vehicles that do not meet regulatory standards for brake performance can face penalties and operational restrictions. By prioritizing slack adjuster maintenance, vehicle operators ensure compliance with safety standards and contribute to overall road safety.

Extended Component Lifespan: Cost-Effective Approach

Worn-out slack adjusters can cause undue stress on other braking system components, leading to premature wear and tear. Conversely, well-maintained slack adjusters help extend the lifespan of brake shoes, drums, and related parts. This results in lower maintenance costs and a more cost-effective operation in the long run.

Enhanced Road Safety: A Collective Responsibility

Ultimately, the importance of properly functioning slack adjusters transcends individual vehicles. When all vehicles on the road are equipped with optimally functioning braking systems, road safety is elevated for everyone. Each properly adjusted slack adjuster contributes to a safer road environment, reducing the potential for accidents and ensuring smoother traffic flow.

Conclusion

The significance of properly functioning slack adjusters reverberates through the intricate network of vehicle performance, safety, and compliance. By recognizing their vital role, vehicle operators can make informed decisions about maintenance, contributing to safer roads and more efficient journeys.

Compliance and Safety Regulations Regarding Slack Adjusters

In the realm of vehicle safety, adherence to regulations is a cornerstone of responsible operation. This chapter delves into the regulatory landscape surrounding slack adjusters, highlighting the legal requirements and safety standards that vehicle operators must navigate to ensure roadworthiness and passenger safety.

Regulatory Framework: Upholding Safety Standards

Government bodies and regulatory agencies set stringent safety standards for vehicles, including their braking systems. Slack adjusters play a critical role in meeting these standards, as they directly impact braking efficiency. Vehicle operators must understand and comply with these regulations to maintain roadworthy vehicles.

Inspections and Compliance Checks: Ensuring Roadworthiness

Regular inspections are essential to ensuring compliance with safety regulations. Inspectors evaluate various components of a vehicle, including slack adjusters, to confirm their functionality and alignment with safety standards. Vehicles that fail to meet these standards can face penalties and operational restrictions.

Maintenance Records: A Paper Trail of Safety

Maintaining comprehensive records of slack adjuster inspections, maintenance activities, and replacements is crucial. These records serve as proof of compliance during inspections and audits. They also demonstrate a commitment to safety and regulatory adherence.

Technological Advancements: Embracing Innovation

As technology evolves, so do safety regulations. Newer vehicles may incorporate advanced brake systems and electronic monitoring mechanisms. Operators must stay updated on these advancements to ensure their vehicles meet the latest safety requirements.

Industry Best Practices: Going Beyond Regulations

While regulations provide a minimum threshold for safety, adopting industry best practices can elevate vehicle safety to the next level. Regular maintenance, proactive inspections, and adherence to safety guidelines contribute to a culture of safety excellence.

Conclusion

Understanding and complying with safety regulations related to slack adjusters isn’t just a legal requirement—it’s a commitment to safeguarding lives on the road. By staying informed, proactive, and engaged with safety standards, vehicle operators contribute to a safer road environment for everyone.

For detailed information, you can contact us at torqueusa.com